sevenfourate

Devotee of OCD

- Location

- Lowestoft, Suffolk

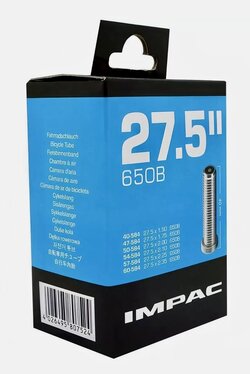

Tubes are for that width yes: https://www.ebay.co.uk/itm/232704459905?var=532215294610Are the tubes definitely designed for that size of tyre? If they are something like 28-35mm, then they will be stretched a little more than they are designed for in a 1.95" tyre.

And have you checked the rim while the tube is out, to make sure there is no sharp object?

People generally nowadays tend to ride at rather lower pressures than they used to, and though 80 isn't likely to be an issue, it would be unusually high for that wide a tyre. Even my 28mm tyres I only run at 80psi (Tubeless would be lower again). There was a time when the professionals would all be running at 110-115psi, they will all now be in the 80-90 range, and that will be on much narrower tyres than yours.

I'm 6'4 (Well i was.......)

and 16 stone on a bad day. Un-clothed.

and 16 stone on a bad day. Un-clothed.Even at 80psi i can easily see some deformation of the contact point of the rear tyre. Not stupid. But seems to show PSI isnt ridiculously high and tyre non-compliant / rock hard effectively for my weight......

And yes ive checked rim numerous times. Plan tonight: is new tube and rim tape (Binning old rim strip). Making sure i've more than covered everything but the sidewalls.