Yellow Saddle

Guru

- Location

- Loch side.

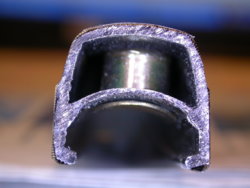

The load taken by the wheel is normally spread evenly around the whole rim, this sort of damage causes a weak spot (where the stress in concentrated) and, once damage like this has occurred, it's more likely to spread.

Oddly, the more expensive the wheel, the more susceptible it's likely to be. A cheap steel wheel has loads of redundancy but lighter designs have thinner walls and so are less able to tollerate damage.

Not saying this wheel will definitely fail, just that it's not something I'd take the risk on

No, it doesn't work like that. The load is not taken evenly. The load is only taken at the bottom, in the load affected zone. This zone is analogous to the tyre's contact patch but bigger. It usually, depending on the number of spokes, span about three spokes. In this zone the spoke tension DECREASES when the wheel is loaded. The rest of the spokes keep their tension and nothing happens in the rest of the wheel.

Stress risers don't come into play here.

Price has nothing to do with it. Key factors are number of spokes, rim profile, type of metal alloy and to a lesser extent, the thickness of the rim walls. There is no redundancy here, that's a different concept.

The wheel has failed. However, failure of this type is not catastrophic and can safely be ridden up to the point where the rim rubs on the brake pads, where it becomes inconvenient to ride. It isn't dangerous and as @Illaveago pointed out in the post above, the OP has probably been riding it like that for many kilometers before discovering the crack.